Design and Technology

Design Processes

Design thinking and communication

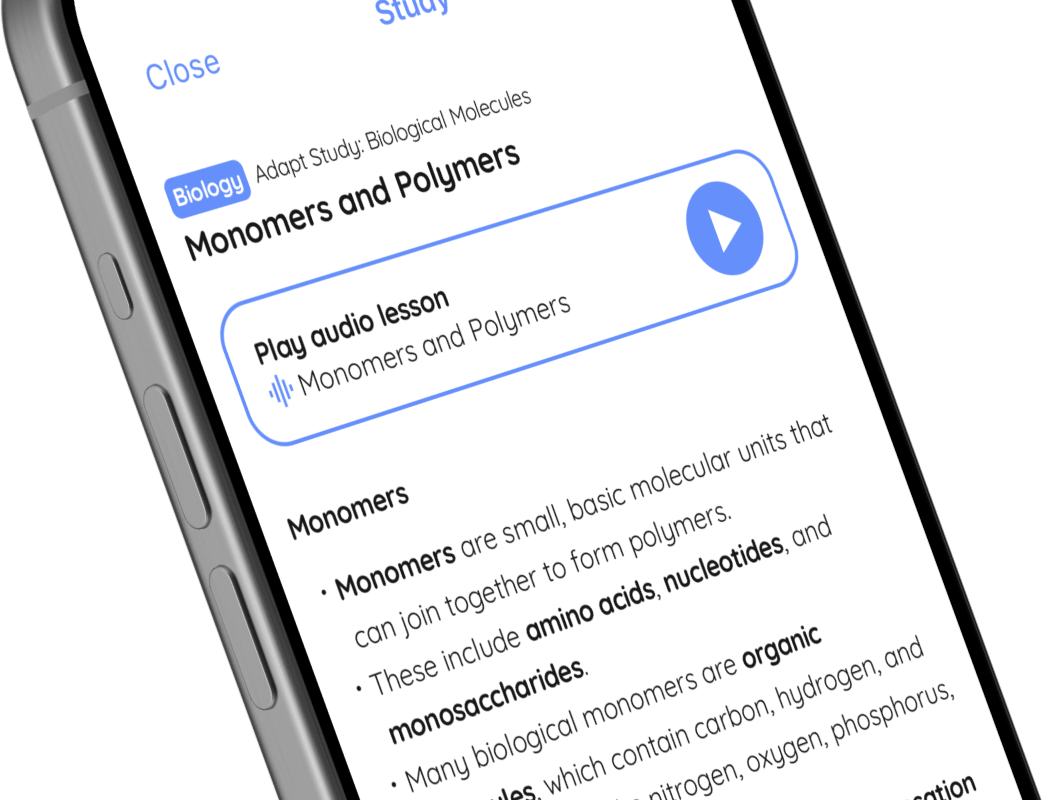

🤓 Study

📖 Quiz

Play audio lesson

Design thinking and communication

Understanding Design Thinking

- Design thinking is a solutions-focused approach that is used to solve complex problems.

- It is a non-linear, iterative process that seeks to understand users, challenge assumptions, and redefine problems.

- Understanding of human needs is essential and is derived mostly from research and investigation.

- Empathy for people's problems or needs is the basis of design thinking.

- It begins with developing a deep understanding of the people for whom are designing the solutions.

Key stages of Design Thinking

- The design thinking process has five stages: Empathise, Define, Ideadte, Prototype, and Test.

- The empathise stage involves gaining an understanding of the problem or situation.

- The define stage involves clearly articulating the problem that needs to be solved.

- The ideate stage involves generating a broad range of ideas for solutions to the problem.

- The prototype stage involves making a physical or digital version of the idea so it can be tested.

- The test stage involves testing the solution in a real-life context and modifying it based on the feedback received.

Design Communication

- Communication is a vital part of any design process. It's the act of conveying intended messages and meanings through various modes.

- Ideas can be communicated verbally, visually, or by using a model or prototype.

- Sketching and drawing are common methods of visually expressing design ideas and concepts.

- With the advent of technology, digital design tools have become critical in communicating design ideas.

- Effective communication helps in iterating and developing the design process further.

Different Forms of Design Communication

- Technical drawings are a form of design communication that is precise and unambiguous.

- Renderings or visualisations are used to show how the final product will appear.

- Storyboarding is a sequential illustration of thoughts, concepts, and ideas.

- Prototypes and models are three-dimensional representations of a design.

- Verbal or written explanations are used to communicate design ideas during presentations.