Design and Technology

Design and Technology in the 21st Century

Design processes

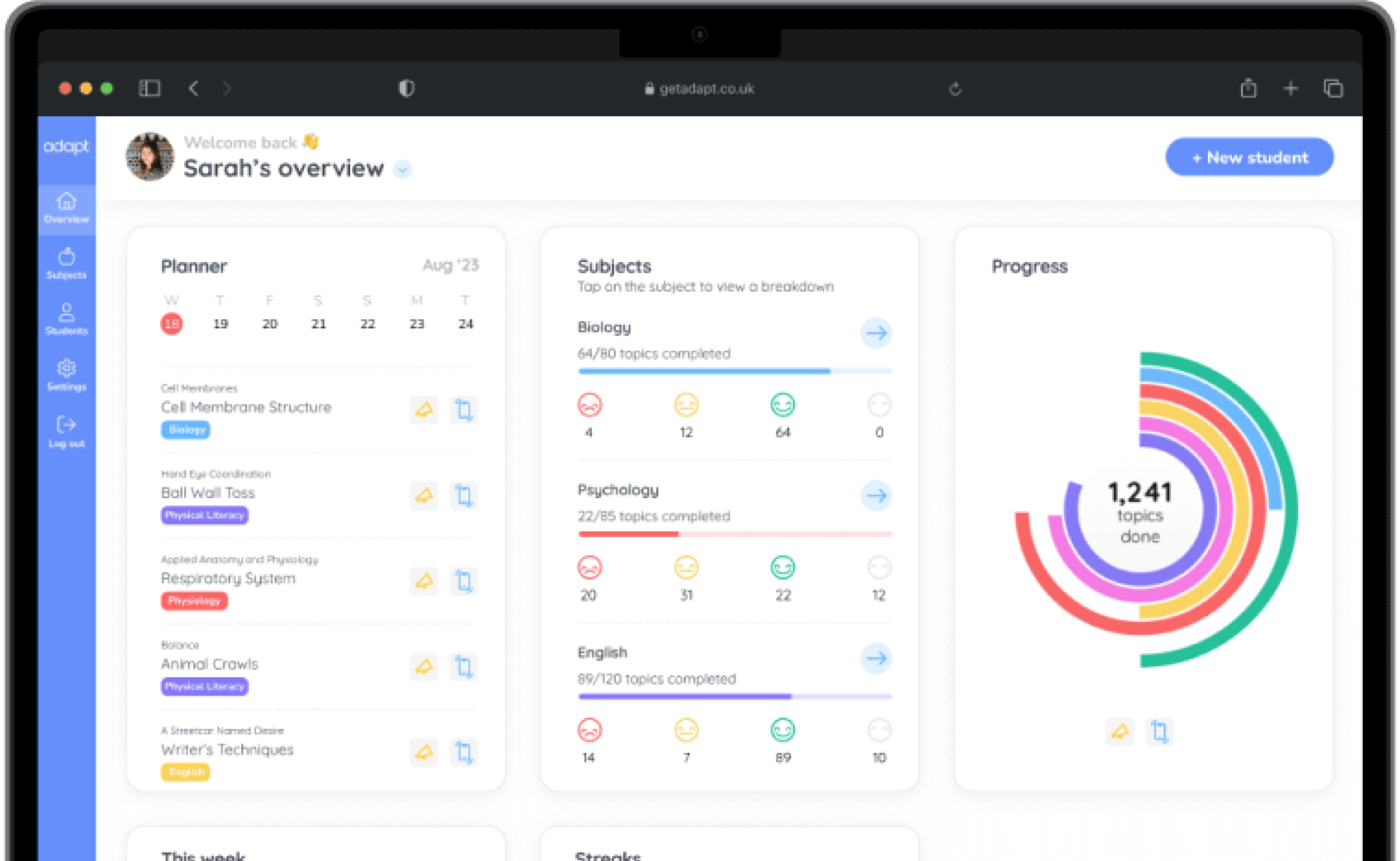

🤓 Study

📖 Quiz

Play audio lesson

Design processes

Design Processes in the 21st Century

Design Briefs

- Initial Brief: Marks the starting point for a new design, prepared by designers.

- Design Interest: Designers should be interested in the design brief which influences design outcomes.

- Design Constraints: Design briefs typically include these, they make limits that can enhance creativity.

Design Requirements

- Design Requirements Matrix: A fundamental tool to articulate the specific needs for a new product.

- Feasibility Studies: To test if the design requirements are practical and viable.

Generating Ideas

- Brainstorming: A technique used to generate as many ideas as possible.

- Morphological Analysis: Breaks down a product into its features, then alters and presents them in different combinations to create innovative designs.

- Pugh Matrix: Used to compare ideas and rank them based on criteria, like cost, functionality, aesthetics.

Product Development

- Prototyping: Testing and improving designs through the making of physical or virtual pre-production examples.

- CAD: Computer-Aided Design allows for precise, easily modifiable representations of products.

- CAM: Computer-Aided Manufacturing allows precision made parts to be produced from CAD files.

Evaluation and Testing

- Functional: Analyses if the product can do what it is designed to do effectively.

- User: Analyses how well the product meets the needs of its target user and how easy it is to use.

- Market Acceptance: Determines how the product is accepted by potential customers.

Commercial Production

- Materials and Components: Selection is crucial in mass production to satisfy factors like cost-effectiveness and suitability.

- Quality Assurance: Ensures consistency, involving pre-set standards, sampling, spot-checks and regular maintenance.

- Large and small scale production: Different scenarios demand different production scales. Considerations include quantities needed, machinery, and processes available, and the complexity of the product.

Sustainability and Future

- Life Cycle Analysis: Identifies areas of environmental impact in a product’s life, from cradle to grave.

- Product Disposal: Considerations for recycling and waste management, biodegradability and environmental impact.

This section provides an overview of key concepts that are integral to understanding design processes in the 21st century. It should be used as a starting point for revision, turbo-charging your understanding of how ideas are converted into saleable, viable products which meet the needs of consumers and respect the constraints of our world. Be sure to delve deeper into these topics to expand your understanding and interpretation.