Textiles

Module: Textile Fibres

Classification of Textiles

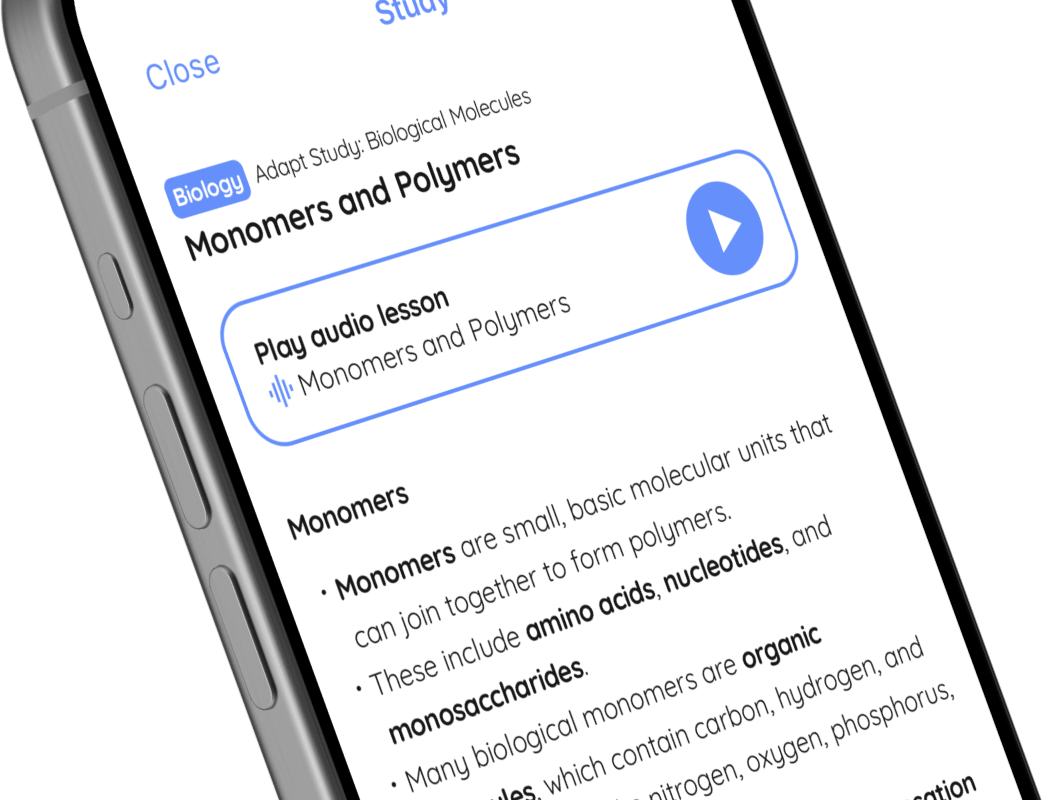

🤓 Study

📖 Quiz

Play audio lesson

Classification of Textiles

Classification of Textiles

Natural Fibres

- Natural fibres are derived from plants, animals, or minerals. They have been used in textile production for thousands of years.

- Animal fibres like wool and silk are proteins. Wool comes from sheep, alpacas, llamas, and other animals. Silk is produced by silkworms.

- Plant fibres include cotton, linen, and hemp. They are composed mainly of cellulose.

- Mineral fibres are less common in textiles. Asbestos is one example, though its use is now banned or restricted because of health risks.

Synthetic Fibres

- Synthetic fibres are man-made fibres produced by chemical synthesis. They are typically made from petroleum-derived chemicals or, less often, from renewable resources.

- Common synthetic fibres include polyester, nylon, and acrylic. These fibres are known for their strength, durability, and resistance to moisture.

- Regenerated fibres are made from natural materials that are chemically altered to form a fibre. Examples include rayon (made from wood pulp) and lyocell (made from eucalyptus trees).

Blended Fabrics

- Blended fabrics combine two or more types of fibres to achieve specific characteristics. They may blend natural and synthetic fibres, different natural fibres, or different synthetic fibres.

- Blends can offer the best attributes of each component fibre. For instance, a cotton-polyester blend might offer the comfort of cotton with the durability of polyester.

- Some blends are designed for specific uses, like activewear, office wear, or home furnishings. Consideration of end use is vital when choosing a blend.

Staples and Filaments

- Fibres can be further classified as staple or filament. Staple fibres are short, typically a few centimetres long. Filament fibres are continuous and can be very long.

- Most natural fibres are staple fibres. An exception is silk, which is a smooth, continuous filament.

- Synthetic fibres can be made as either staples or filaments. When synthetic staples are used, they are often cut to resemble natural fibres.

Textile Processing

- After fibres are prepared, they are often spun into yarns. This process transforms the fibres into a form that can be woven or knitted into fabrics.

- Various weaving techniques can be used to create the final fabric. Some weave structures include plain weave, twill, and satin weave.

- Fabrics can also be made from non-woven processes, including felting, bonding, and crochet.