Engineering

Materials and Their Properties

Material properties (strength, ductility, conductivity, etc.)

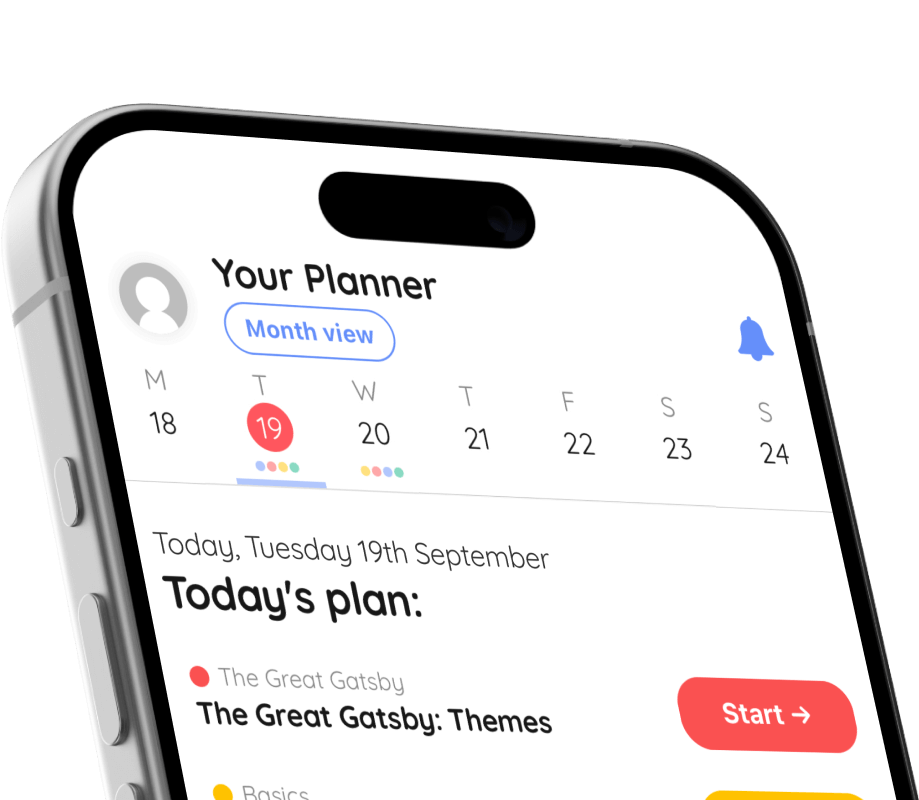

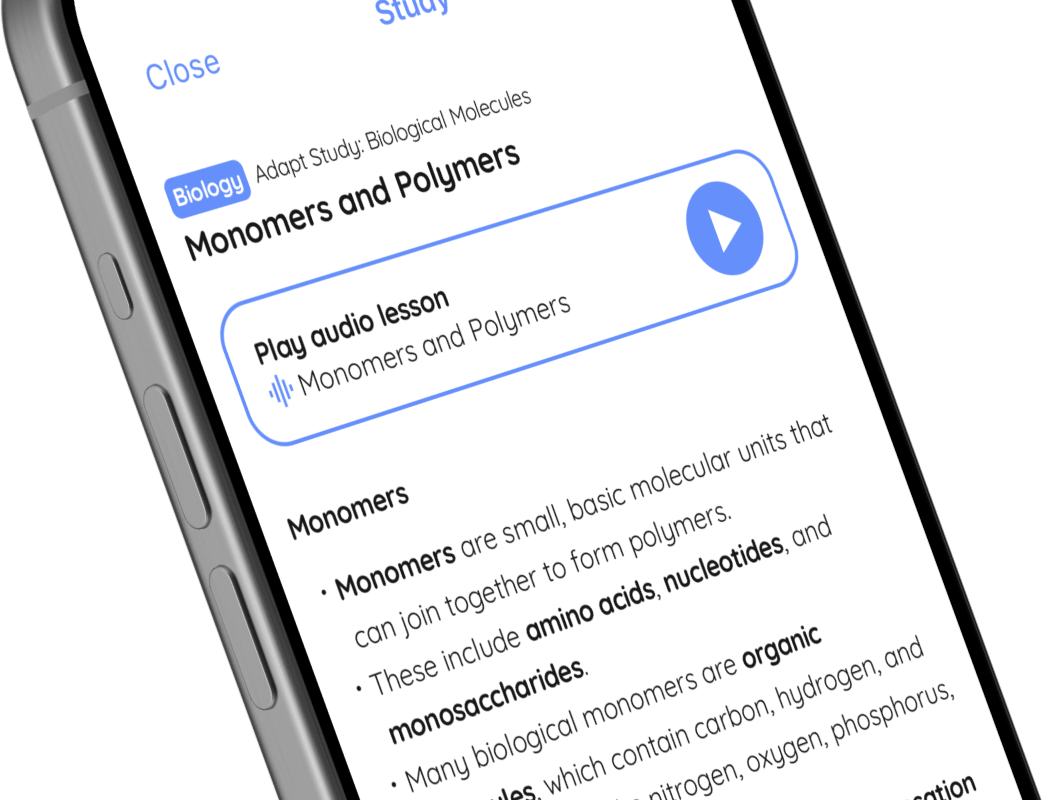

🤓 Study

📖 Quiz

Play audio lesson

Material properties (strength, ductility, conductivity, etc.)

Material Properties Overview

- The properties of materials include various characteristics that determine their applications and suitability in different conditions.

- Understanding these properties are vital to engineers, as it governs their choice for specific applications.

Strength

- Strength describes the ability of a material to withstand a force without deforming or breaking.

- The ultimate tensile strength (UTS) is the maximum stress that a material can withstand while being stretched or pulled before breaking.

- Compressive strength refers to the capacity of a material to withstand loads tending to reduce size.

Ductility

- Ductility is a material's ability to deform and change shape without breaking.

- This property allows materials to be drawn out into a thin wire.

- Materials such as gold and copper demonstrate high ductility.

Conductivity

- Conductivity pertains to the ability of a material to transfer heat or electricity.

- Materials with high electrical conductivity, like copper and aluminum, are often used in the construction of electrical wires.

- Thermal conductivity refers to the ability to transfer heat. Materials with high thermal conductivity, such as copper, are often used in heat sinks or cooking utensils.

Malleability

- Malleability is related to ductility and defines how easily a material can be bent or hammered into various shapes without breaking or cracking.

- Materials like gold and silver have high malleability.

Durability

- This property describes the ability of a material to resist wear, decay and degradation over time.

- This is a vital consideration for structures or machinery expected to endure long durations of use or harsh weather conditions.

Density

- Density refers to the mass of a material per unit volume.

- It's important when considering the weight and stability of a structure, especially in transportation and construction.

Hardness

- Hardness is a material's ability to resist deformation, usually by indentation or scratching.

- Hardness testing often helps to reveal other material properties such as strength or ductility.

Remember to jot down diagrams, examples, and equations where necessary to aid your understanding. It's also useful to relate these properties to real-life applications for a better grasp of their importance in engineering.