Automotive

Health and Safety in the Automotive Work Environment

Health and safety legislation

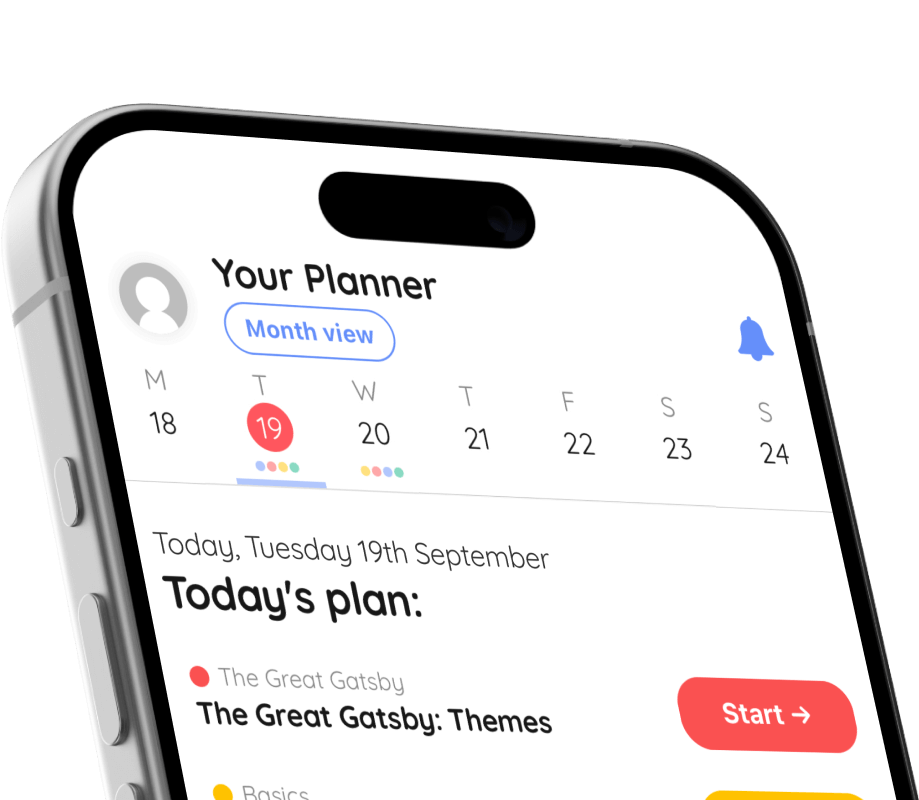

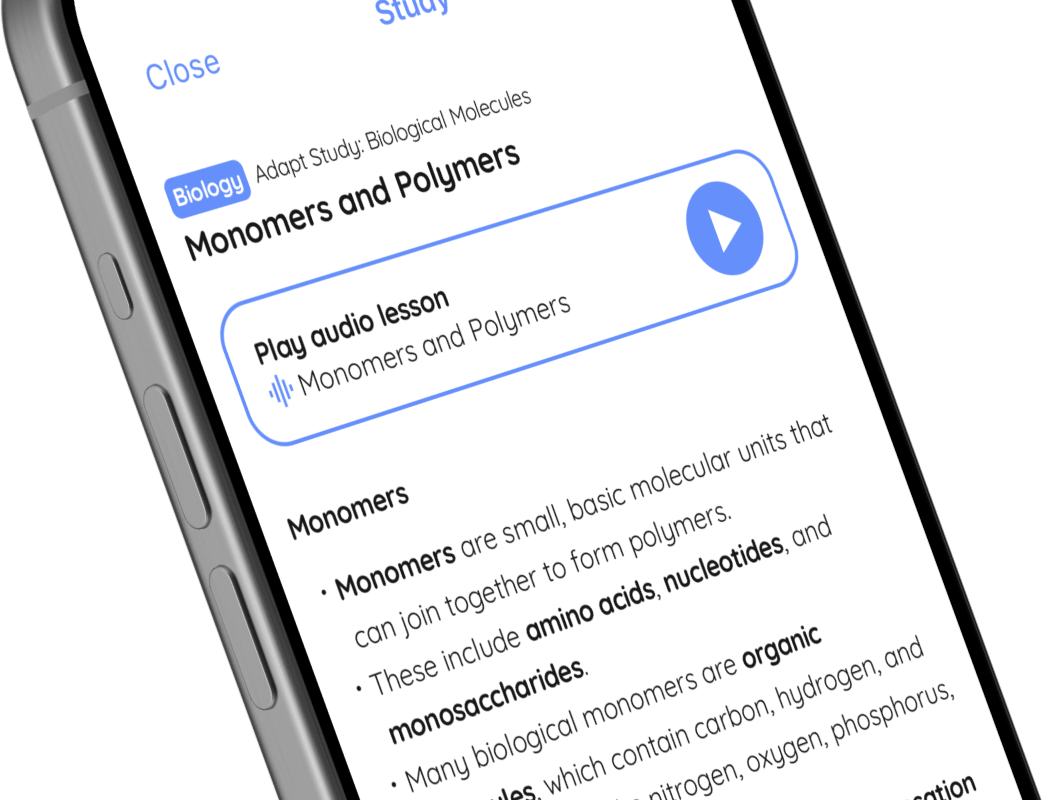

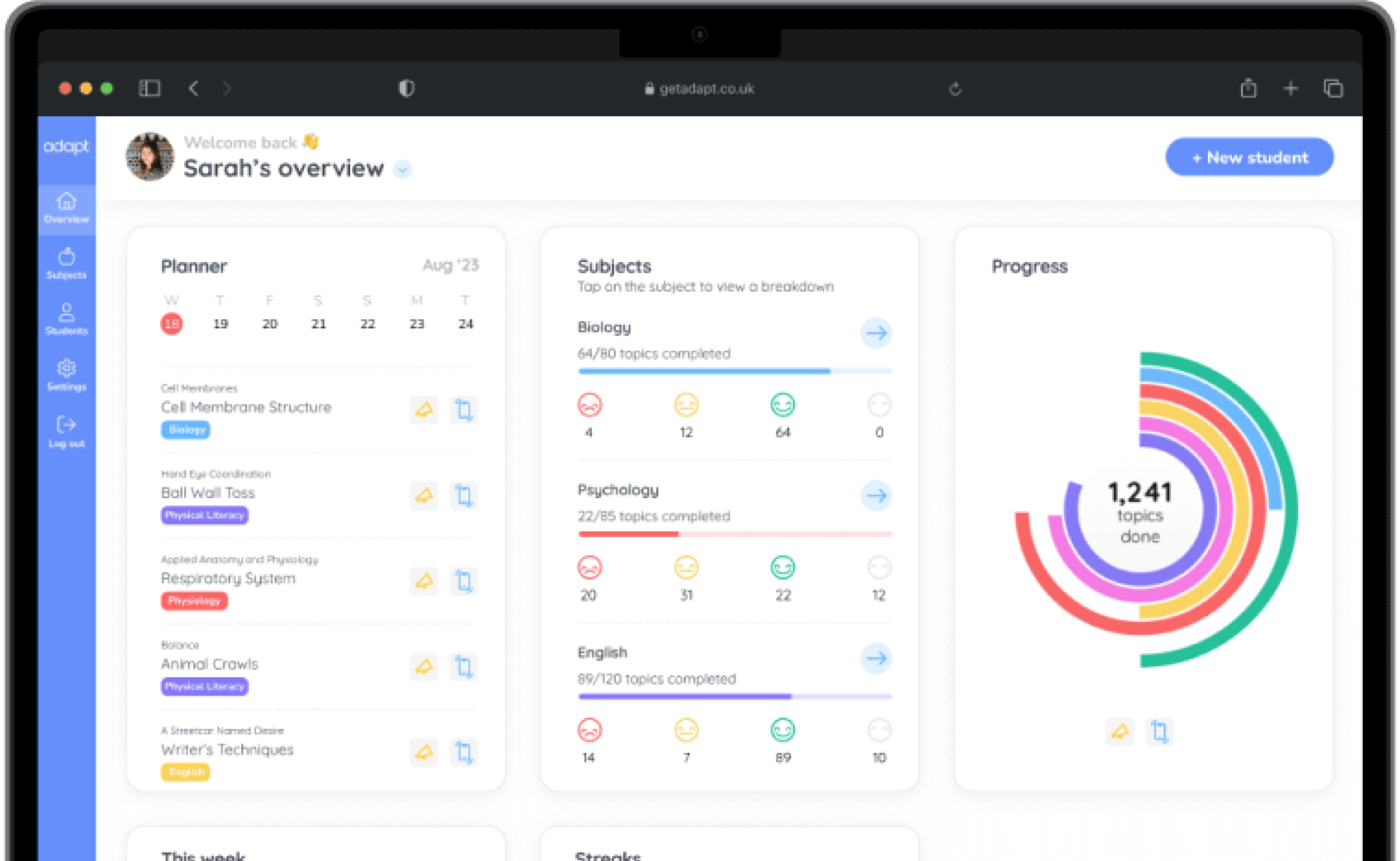

🤓 Study

📖 Quiz

Play audio lesson

Health and safety legislation

Health and Safety Legislation in the Automotive Industry

Understanding Legislation

- The Health and Safety at Work Act 1974 (HSWA) is the primary piece of legislation covering occupational health and safety in the UK which also applies to the automotive industry.

- It sets out the general duties which employers have towards employees and members of the public, and employees have to themselves and each other.

- HSWA is enforced by The Health and Safety Executive (HSE) and local authorities.

- HSE also provides guidance, advice, templates and tools for businesses to ensure they comply with the legislation.

Responsibilities of Employers

- Employers are legally obliged to ensure the health, safety and welfare at work of all their employees.

- They are responsible for providing a safe and secure working environment, safe systems of work, safe tools and machinery, and appropriate training and supervision.

- Employers must carry out risk assessments to identify potential hazards and decide how to prevent harm.

Responsibilities of Employees

- Employees have a duty to take care of their own health and safety and that of others who may be affected by their actions at work.

- They must cooperate with employers and co-workers to help everyone meet their legal requirements.

- Employees should not interfere with anything provided to safeguard their health and safety, follow provided instructions, and report any health and safety concerns to their employer.

Control of Substances Hazardous to Health (COSHH)

- The COSHH Regulations 2002 require employers to control substances that are hazardous to workers' health.

- In the automotive industry, this can include solvents and paints, petrol and diesel, adhesives, oils, brake fluids and battery acids.

- Measures might include reducing the use of a hazardous substance, isolating workers from exposure, and providing protective workwear.

Personal Protective Equipment (PPE)

- The Personal Protective Equipment at Work Regulations 1992 requires employers to provide appropriate protective clothing and equipment for their employees.

- Examples in the automotive industry include steel-toe boots, gloves, overalls, eye protection, and head protection.

Workplace (Health, Safety and Welfare) Regulations 1992

- These regulations ensure that workers have suitable welfare facilities including toilets, washing facilities, drinking water, and seating for breaks.

- They also contain requirements for certain aspects such as general cleanliness, temperature, space, lighting and ventilation in the workplace.

Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR)

- RIDDOR 2013 requires employers, the self-employed and those in control of work premises to report certain serious workplace accidents, occupational diseases and near misses to HSE.

- In the automotive industry, reportable injuries might include major injuries, like serious burns, mechanical contact injuries (being caught between rolling, moving or falling objects), and dangerous incidents like the collapse or failure of load-bearing parts.